committed to using the latest advances in technology to maintain food security. Blockchain technology is new, but we have been working in the retail food space for years. We know the challenges retailers face. We understand cold chain. And we already have a platform that will form the foundation of ZetoChain. We have the best position to take advantage of this powerful new technology, and provide end-to-end solutions to retailers that will help them improve efficiency, save money, protect their brands, and introduce full transparency into their cold chain.

ZetoChain will change the latest practices and methodologies in cold chain management, offer a level of transparency that will become the industry standard, and bring unparalleled cost and time efficiency to highly competitive industries.

The purpose of the project. Provides uninterrupted and fully controlled supply of goods that require cold storage and transportation (transportation), using a decentralized smart platform, Zeto. Thanks to ZetoChain technology, consumers and manufacturers will be able to check and monitor the quality of products delivered using mobile applications.

Consumer food and beverage demand is increasing every year. With world population growth and income levels, by 2050 this figure will grow by another 60%. This factor affects an elaborate and fragmented supply chain of food with a large number of players traveling long distances.

The food retailer is responsible for the quality of the products offered and their compliance with the standards. However, they do not know how the products provided are handled. This makes them vulnerable and unable to protect themselves from the risk of contaminating food.

With ZetoChain, retailers, restaurants and companies throughout the global food service industry can be confident that the food they sell is of the highest quality. They will have a record to support this quality, which they can share with customers, producers, and all parties in the chain.

Customers will be able to use their own smartphone to scan labels for meat, dairy products or any fresh products they want to buy. With their gadgets, they can track the product to the source to ensure that it has been processed, transported and stored in a safe environment throughout the life cycle.

ZetoChain will change the latest practices and methodologies in cold chain management, offer a level of transparency that will become the industry standard, and bring unparalleled cost and time efficiency to highly competitive industries.

The purpose of the project. Provides uninterrupted and fully controlled supply of goods that require cold storage and transportation (transportation), using a decentralized smart platform, Zeto. Thanks to ZetoChain technology, consumers and manufacturers will be able to check and monitor the quality of products delivered using mobile applications.

Consumer food and beverage demand is increasing every year. With world population growth and income levels, by 2050 this figure will grow by another 60%. This factor affects an elaborate and fragmented supply chain of food with a large number of players traveling long distances.

The food retailer is responsible for the quality of the products offered and their compliance with the standards. However, they do not know how the products provided are handled. This makes them vulnerable and unable to protect themselves from the risk of contaminating food.

With ZetoChain, retailers, restaurants and companies throughout the global food service industry can be confident that the food they sell is of the highest quality. They will have a record to support this quality, which they can share with customers, producers, and all parties in the chain.

Customers will be able to use their own smartphone to scan labels for meat, dairy products or any fresh products they want to buy. With their gadgets, they can track the product to the source to ensure that it has been processed, transported and stored in a safe environment throughout the life cycle.

Problem. There is no secret that the high growth rate of food consumption in Europe and America is characterized every year by perseverance. Every year the requirements for product quality continue to grow. Consumers want to see safe products with quality assurance. In turn, retailers also want to follow the rules set for transportation, storage, and product movement. Especially with regard to items with special conditions (temperature, humidity, etc.) Greatly determine safety when they appear on store shelves. Of course, companies want to retain their brand names and partners. However, in this rather inconvenient chain - from the conveyor outlet to the consumer basket - you may lose some of the links out of control, which, unfortunately, has happened and is still happening.

Technology. Team Zeto has a lot of experience in the sale of food products. This skill allows the introduction of blocking technology into existing systems. Zeto understands that today's retailers need smart solutions that enable the use of advanced technology to reduce related costs and risks. Undoubtedly, the leading role in solving the use of intelligent technology is played by increasing profits and strengthening brand reputation. Zeto proposes to introduce SaaS technology (Software as a Service) for the global commercial refrigeration industry. Zeto uses data analysis and IoT (Internet of things) technology to operate ZetoChain's smart platform ecosystem to manage cooling equipment,

ZetoChain provides cloud-based SaaS answers to the business cooling industry worldwide. With ZetoChain, food retailers, restaurants and organizations throughout the food industry around the world will realize that the food they offer is of the highest quality. Also, they will have a record to degrade this quality, which they can provide to clients, makers, and all meetings that are exposed to harsh element chains. Clients will have the capacity to use their phones to filter names on any meat, dairy products, or crunchy foods they want to buy or consume. They will then be able to follow the item back to its source to see that it is handled, transported, and kept in a sheltered situation during its life cycle.

The strategy used by food retailers is currently available to control and transparency needs, and that affects client certainty. Create the observed and controlled after touching the base in their office, but the data they get about the shipping treatment before that point is second-hand, and generally unreliable. If there is a problem of dirt or blackmail that appears, retailers are regularly left forgot while trying to find an excuse, and can not be sure to maintain similar issues.

Platform Advantages

Transparency and trust

1.Significant improvement in food safety standards.

2.Increase customer trust by improving communication and transparency.

3.Reduce the risk of losing the brand reputation.

4'Increase transparency and trust between all parties.

5.Minimize the risk of scandal with PR.

2.Increase customer trust by improving communication and transparency.

3.Reduce the risk of losing the brand reputation.

4'Increase transparency and trust between all parties.

5.Minimize the risk of scandal with PR.

Waste prevention and cost savings

1.Minimize waste by isolating problems in the cold chain through real-time warnings and the possibility of taking

precautions.

precautions.

2.Prevent retail losses by checking for safe product handling.

Compliance with security standards

1.Automation of human tasks, such as temperature monitoring and recording

2.Implementation of targeted strategies for managing cold chains (for example, products with the shortest expiration

date in the distribution center are sent to the nearest supermarket).

3.Ensuring traceability in seconds, not weeks.

4.Remove the risk of unauthorized access by using cold chain notes using scratch-resistant sheaths, data encryption,

and smart contract blocking.

5.strict food safety regulations (HACCP, FSMA, FSIS).

2.Implementation of targeted strategies for managing cold chains (for example, products with the shortest expiration

date in the distribution center are sent to the nearest supermarket).

3.Ensuring traceability in seconds, not weeks.

4.Remove the risk of unauthorized access by using cold chain notes using scratch-resistant sheaths, data encryption,

and smart contract blocking.

5.strict food safety regulations (HACCP, FSMA, FSIS).

Principle of operation

Workers assign product code to label using app. The Zeto platform records smart contracts for this product using the appropriate parameters (permissible temperature and humidity ranges).

Products are placed in the refrigerator and detected by Zeto monitoring systems installed in real time. If there is a problem, the responsible user is immediately alerted.

Products are placed in the refrigerator and detected by Zeto monitoring systems installed in real time. If there is a problem, the responsible user is immediately alerted.

The product moves from the cooling store to the refrigerator, where the Zeto monitoring system is installed in real time. The system automatically detects that the goods have been moved from cold store to car without user action. If the product is marked as unsafe, the related user will be notified, and the driver rejects it. Received products are monitored in real time during transit, and drivers are warned about possible problems.

Workers receiving shipping at retail stores using the mobile app. The items are moved to the refrigerator, where the Zeto monitoring system is installed in real time. The on-store product safety notes are updated automatically with relevant information.

Items are tracked while in a retail store. Customers can use their own smartphone to scan product labels to view processing information before purchasing. When placing an order, the Point of Sale (POS) system verifies that the food is safe and notes that the smart contract has been completed.

OUTSTANDING FEATURES FROM ZETOCHAIN

Here is an amazing feature of ZetoChain:

1.PROCESSOR FOOD - Track food temperature throughout the processing chain in real time and on departure.

2.AIR / SEA / TRUCK - Track product temperature during transit in real time and on arrival.

3.TRANSPORT - Track the storage temperature of the product in the warehouse and on departure.

4.DISTRIBUTION - Track food temperature in cold storage truck and at delivery point.

5.STORE - Track the storage temperature of refrigeration equipment.

2.AIR / SEA / TRUCK - Track product temperature during transit in real time and on arrival.

3.TRANSPORT - Track the storage temperature of the product in the warehouse and on departure.

4.DISTRIBUTION - Track food temperature in cold storage truck and at delivery point.

5.STORE - Track the storage temperature of refrigeration equipment.

Conclusion. In my opinion, this project is quite promising. The idea of the project is simple and transparent. The project team consists of 20 members, founders and developers, including 5 advisors. The team itself is experienced, specialists from the IT segment and from the logistics sector and the food supply is represented. Of course, the project was not spontaneously born, well-prepared project documentation, colorful informative sites with graphics and textual information, detailed statistical studies and data presented. To date, the project has competitors, but the technology offered by Zeto has no analogues so far. Such industries as goods movements have large cash flow, but the main motivation for successful activities is client-oriented and quality of goods,

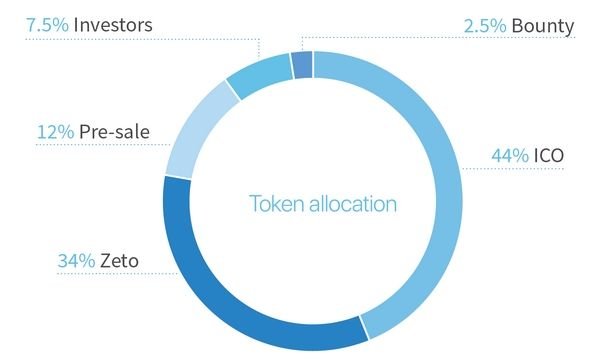

Sale details of token ZetoTokens:

1.Date of sale: from 9 to 31 July

2.Token Type: Ethereum ERC20

3.Application method: ETH

4.Total number of tokens: 340 million ZetoTokens

5.Sale for sale: 150 million ZetoTokens

6.Allocated for pre-sale: 40.8 million ZetoTokens

7.Gift prize: 8.5 million. ZetoTokens

8.For private investors: 24.7 million ZetoTokens

9.Reserved for Zeto: 116 million.

10.Price ZetoTokens: $ 1/10 Token

2.Token Type: Ethereum ERC20

3.Application method: ETH

4.Total number of tokens: 340 million ZetoTokens

5.Sale for sale: 150 million ZetoTokens

6.Allocated for pre-sale: 40.8 million ZetoTokens

7.Gift prize: 8.5 million. ZetoTokens

8.For private investors: 24.7 million ZetoTokens

9.Reserved for Zeto: 116 million.

10.Price ZetoTokens: $ 1/10 Token

Token distribution

Distribution of funds

Main Team

Stephen Slattery - Executive Director

Stephen has been leading Zeto since it was founded in 2011. After receiving qualified engineers in electronic and computer technology, he worked with the company's software company, where he became acquainted with the IoT world.

Stephen has been leading Zeto since it was founded in 2011. After receiving qualified engineers in electronic and computer technology, he worked with the company's software company, where he became acquainted with the IoT world.

Tom Kelleher - Director of Sales

Have more than 20 years experience in various fields of international sales and marketing management. He works with companies in the retail, dairy and pharmaceutical industries. Creating teams to facilitate scaling of products and services in global markets. Join Zeto by 2016.

Have more than 20 years experience in various fields of international sales and marketing management. He works with companies in the retail, dairy and pharmaceutical industries. Creating teams to facilitate scaling of products and services in global markets. Join Zeto by 2016.

Jonathan Harrington - Technical Director

Having more than 13 years of experience in the finance and telecommunications industry, working on hardware and software platforms from the leadership level. For the last 5 years he led the Zeto R & D team.

Having more than 13 years of experience in the finance and telecommunications industry, working on hardware and software platforms from the leadership level. For the last 5 years he led the Zeto R & D team.

Michael Slattery - Executive Director

Michael has 40 years of experience working with industrial equipment as an engineer. First of all, he is involved in his own business related to the dairy, health and food sectors. He predicted the revolution in IoT and has been working since 2009, building an intelligent cooling system that installs Zeto in 2011.

Michael has 40 years of experience working with industrial equipment as an engineer. First of all, he is involved in his own business related to the dairy, health and food sectors. He predicted the revolution in IoT and has been working since 2009, building an intelligent cooling system that installs Zeto in 2011.

For more information visit;

Website: https://zetochain.com/

Twitter: https://twitter.com/zetochain

Facebook: https://fb.me/zetochain/

Telegram: https://t.me/zetochain

Whitepaper: https://zetochain.com/static/docs/ZetoWhitepaper.0aaa18e97dbb.pdf

Twitter: https://twitter.com/zetochain

Facebook: https://fb.me/zetochain/

Telegram: https://t.me/zetochain

Whitepaper: https://zetochain.com/static/docs/ZetoWhitepaper.0aaa18e97dbb.pdf

By Martin Vunk :

Tidak ada komentar:

Posting Komentar